Back | Next | Home

Missoula Technology &

Development Center

| Table

of Contents Back | Next | Home |

Missoula Technology & Development Center |

Treatment of Petroleum-Contaminated Soils

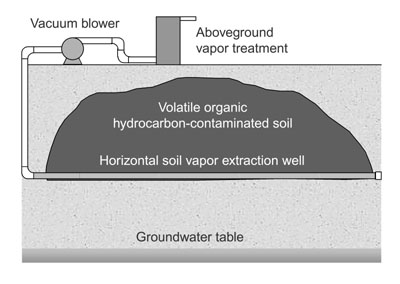

Soil vapor extraction (SVE) is an in situ technology that uses flowing air (soil gas) to volatilize volatile organic compounds (VOCs) in the contaminated soil, removing the contaminant from the soil (figure 14). The air flow is created by vacuum blowers attached to extraction wells installed in the unsaturated zone. The soil gas containing the VOCs is treated aboveground to remove the VOC. The treated air is discharged into the atmosphere. This step of the process will produce a waste that requires proper disposal.

Figure 14—Schematic of a typical soil vapor extraction system.

Once the flow of soil gas is established in the porous medium, volatile components contained in the soil preferentially partition into the flowing soil gas from the liquid phase VOC contained in the pore space, from the portion of compound that is dissolved in the soil water, and from the portion of the compound that is adsorbed onto soil particles. Compounds that are readily removed by venting were discussed previously.

Soil vapor extraction wells can be installed vertically, horizontally, or at an angle. Conventional water well drilling techniques can be used to install SVE wells. Alternatively, SVE wells can be installed with excavation equipment if the depth of contamination is shallow. For instance, horizontal wells can be installed with directional drilling techniques or by using a backhoe for trenching.

Soil vapor extraction has been used extensively in Alaska to treat petroleum-contaminated soils (information provided by Hartcrowser, appendix C). The most notable cold-related problem has been freezing of condensed water in above-ground piping. Heating elements and insulation have been used to reduce this problem. Figure 15 shows insulation around a typical SVE extraction wellhead. Low temperatures reduce the volatility of the volatile fraction of the organics, slowing their removal. As in the ex situ venting process described above, heating the soil may increase the rate of removal.

Figure 15—Insulation installed around a typical SVE extraction well.

In any soil, high soil moisture decreases the soil's permeability to air. In areas that experience high precipitation, the mass removal rate of volatile compounds will be reduced during periods of water infiltration. Covering the surface of the contaminated soil region will reduce infiltration. Covering the contaminated region helps remove contaminants by extending the lateral influence of the flowing air.

Soil vapor extraction requires single- or three-phase electrical power for the blowers, which will be a problem in remote regions. The problem is compounded by heterogeneities in soil properties that may limit flow, slowing the removal of contaminants by SVE. One option is to use SVE technology to remove a large fraction of the volatile contaminant from the soil and then use an alternate method to further reduce the contaminant, such as an ex situ technique or excavation and disposal of the remaining contaminated soil. This methodology makes good practical sense. Experience has shown that large fractions of volatile organics in contaminated soils are reduced in a short period of time by SVE. The volatile compounds that remain in the soil are probably in areas of low permeability. Removal of contaminants from these areas is dominated by diffusion transport processes, which are slow compared to advective transport processes (motion along a gradient) that are dominant in the zones of soil with relatively high permeabilities.

Application of this soil treatment procedure in cold, remote regions would be a two-step process. Step one would be to use SVE to remove the bulk of the volatile contaminants during the warmer summer months. Depending on the soil type and the extent of contamination, this step may be completed quickly. Step two would be to remove the remaining contaminant by excavating the soil and attempting to treat it ex situ by one of the processes described above, or by properly disposing of the contaminated soil. An alternative to excavation would be to switch to a passive in situ treatment technique such as barometric pumping (as described in the next section) after the bulk of the contaminant has been removed by SVE.

Table 15 shows the items to be considered when developing a cost estimate for SVE. The assumptions include:

| Cost estimating factors | |

|---|---|

| • | Mobilization and demobilization. |

| • | Piping. |

| • | Slotted pipe or well screen. |

| • | Gravel pack for area around screens. |

| • | vvvvBlower. |

| • | Liner (if required). |

| • | Housing for the blower and generator. |

| • | Fuel for the generator—Estimated fuel consumption is one-half gallon per hour. |

| • | Exhaust gas treatment system. |

| • | Sampling of off gas to monitor treatment progress. |

| • | Confirmation sampling—The number of samples depends on the size of the contaminated site and on the regulatory agency. |

| • | Accommodations at the site during system insallation. |

| • | Operation and maintenance visits. |

|

|

Back | Next Table of Contents |

Missoula Technology & Development Center |