James "Scott" Groenier, Project Leader

Choosing a rail system for trail bridges and boardwalks can be difficult. This tech tip explains the differences between three basic rail systems, discusses Forest Service requirements, and provides a simple process for determining the basic rail system that best fits your structure.

- Rail systems are important safety features

on trail bridges and boardwalks.

- Three basic rail systems can be used for

trail bridges.

- In backcountry and wilderness settings

an analysis may show that rails are not

needed and that curbs can be used.

- A relatively simple process can be used to determine the type of rail system that should be used with a Forest Service trail bridge or boardwalk.

Safety and Other Concerns

Public safety must always be the first consideration when you are selecting a rail system. Safety requirements are determined primarily by the needs of the expected trail users. Esthetics and the rail system's fit with the appropriate Recreation Opportunity Spectrum (ROS) classification are secondary considerations that often can be met through material selection and/or coatings. Proper signs are another issue that may be a concern when constructing trail bridges. Consult the "Sign and Poster Guidelines for the Forest Service" (EM 7100–15) for more information.

Codes and RegulationsThe three basic rail systems typically used for trail bridges include:

- Urban and high-risk areas (IBC-based)—The 2006 International Building Code (IBC) refers to the rail systems attached to buildings as guards. These rail systems are recommended on trail bridges in urban settings or high-use areas (figures 1 and 2). The IBC section 1013, "Guards," requires stairs, platforms, and landings higher than 30 inches to have guards (rail systems) at least 42 inches high measured from the leading edge of the tread to the top of the guard. A 4-inch sphere must not pass through the lower 34 inches of the rail system and an 8-inch sphere must not pass through the upper area of the rail system (between 34 and 42 inches). The IBC section 1607, "Live Loads," requires guards to resist a uniform load of 50 pounds per linear foot or a single concentrated load of 200 pounds applied in any direction at the top of each rail. The guard must transfer the load through the supports to the structure. Most intermediate rails are mounted vertically so children cannot climb on them.

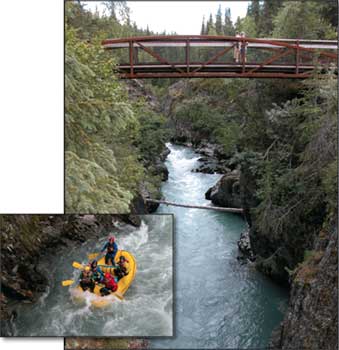

Figure 1—These rail systems meet the requirements

of the 2006 International Building Code.

Figure 2—Wire mesh will prevent children from falling while

they are watching whitewater rafters

on the river below

(Chugach National Forest, AK).

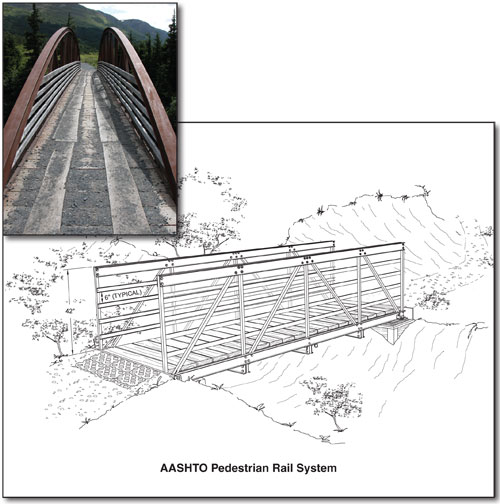

- Rural and moderate-risk areas (AASHTO-based)—Rail systems on trail bridges frequently used by bicycles and other moving traffic (figure 3) should meet the American Association of State Highway and Transportation Officials "AASHTO LRFD (Load and Resistance Factor Design) Bridge Design Specifications" (AASHTO 2007). Section 13, "Railings," requires a railing (rail system) at least 42 inches high for pedestrian traffic and at least 54 inches high for bicycle or equestrian traffic. A 6-inch sphere must not pass through the lower 27 inches of the rail system and an 8-inch sphere must not pass through the upper area of the rail system (higher than 27 inches). A safety toe rail (AASHTO's terminology) or curb should be provided. The rail spacing requirements do not apply to support rails and posts for chain link or metal fabric fence. Mesh in chain link or metal fabric fence should have openings no larger than 2 inches. The design live load for railings is 50 pounds per linear foot, both transversely and vertically, acting simultaneously. In addition, each rail will be designed for a concentrated load of 200 pounds, which shall act simultaneously with the above loads at any point and in any direction at the top of each rail. Note: Railings (rail systems) are normally constructed horizontally so wheels will not catch on them.

Figure 3—This ATV bridge meets the AASHTO rail system requirement.

Rails are horizontal so they will not catch on tires or handlebars.

- Remote and low-risk areas (OSHA-based)—The IBC and AASHTO rail systems are complicated and expensive and should be used for moderate- to high-risk areas. Remote locations (figure 4) are typically low-risk areas and may not have to meet these standards. The Occupational Safety and Health Administration (OSHA, CFR 29, Part 1910, Subpart D) refers to a rail system as a standard railing. These systems provide safety without complication and are widely accepted for protecting industrial workers. While OSHA requirements apply only to the workplace, its standard railing is a good choice for public trail bridges in low-risk areas. OSHA 1910.23 requires every open-sided floor or platform 4 feet or more above the adjacent floor or ground level to be guarded by a standard railing on all open sides except where there is an entrance to a ramp, stairway, or fixed ladder. A standard railing shall consist of a top rail, intermediate rail, and posts. The railing shall have a vertical height of 42 inches nominal from the upper surface of the top rail to the floor, platform, runway, or ramp. The intermediate rail shall be about halfway between the top rail and the floor, platform, runway, or ramp. A bottom rail (called a toeboard by OSHA) is recommended. For pedestrian trail bridges, the vertical distance between steel rails must not exceed 19 inches and the vertical distance between wood rails must not exceed 15 inches. The completed rail system shall be capable of withstanding a load of at least 200 pounds applied in any direction at any point on the top rail.

Figure 4—This pedestrian trail bridge (shown in photo) in a remote

area

has a simple rail system consisting of a top rail,

middle rail,

bottom rail,

and posts.

The Forest Service, U.S. Department of Agriculture, railing requirements for trail bridges are a blend of the three rail systems already discussed. The Forest Service requires railings (rail systems) for all trail and pedestrian bridges. However for trail bridges and boardwalks, railings may be replaced by curbs (figure 5) when an appropriate analysis has been completed, as noted in the Forest Service Handbook (FSH) 7709.56b, Transportation Structures Handbook, section 7.66, "Railings." The analysis should identify and evaluate the structure's potential users and determine whether the potential hazards along the trail are the same or greater than the hazards of a bridge without a railing. The analysis should also include the possibility of using a railing (rail system) on only one side of the bridge.

Because trails in rural and urban ROS settings are likely to have small children and less experienced users, a railing (rail system) is warranted in most instances. In backcountry or wilderness settings, where users normally are more experienced, railings may not be needed. If the trail on which the bridge is located has dropoffs that are more hazardous than dropoffs from the trail bridge, a rail system probably is not required. As a general rule, railings are required for bridges or boardwalks on any trail with a dropoff of 4 feet or more that is not in a remote area or on a remote trail with a dropoff of 8 feet or more. All trail bridges that do not have a railing (rail system) must have a curb.

Figure 5—Curbs may be used in place of railings on trail bridges

and boardwalks if an analysis shows that a rail system is not warranted.

There have been no definitive studies of railing systems for all-terrain vehicle (ATV) trails. In February 2002, Jasen Neese completed an unpublished report for the Missoula Technology and Development Center (MTDC), "Trail Bridge Railing Geometry: Summary of Work and Preliminary Recommendations." Neese's report relied on "Design and Evaluation of Two Bridge Railings for Low-Volume Roads" (Faller and others 1995). Neese concluded that railings should be designed to withstand a load of 2,250 pounds or greater. This loading would substantially increase the size and cost of the bridge railings. An alternative design would require curbs for ATV trail bridge railings similar to the timber curbs currently used for low-volume road bridges (figure 6). For road bridges, the Forest Service requires curbs to be at least 15 inches high with the top curb member at least 6 by 10 inches.

Figure 6—Curbs on trail bridges used by ATVs could be subjected to

high-impact loads. Consider using curbs similar to those used on

highway bridges for

low-volume roads (shown in photo). The

recommended height of curbs for ATV trail bridges

has not been determined.

MTDC considered using Barrier 7 software to simulate crash tests of railing designs. The software uses finite element analysis to model the protective shell around the driver. Because ATVs have no protective shell around the rider, they cannot be modeled by Barrier 7 software. After discussing the requirements of this software with the University of Nebraska, the center decided that it was too costly for the limited data that would be gathered. The model would have to be calibrated by crash testing several ATVs at a cost of $100,000 or more.

An alternative recommendation for ATV bridge railings would be to keep trail bridges as narrow as possible to reduce the angle at which ATVs glance off the curbs. A 42-inch high pedestrian railing also may have to be installed if analysis determines that it is needed. If no curbs are installed, a rub rail should be installed at the height of ATV tires so the tires do not hit the structure.

Rail System SelectionSelection of a rail system depends on the trail bridge's location and its users, but public safety should be the main objective. Questions to consider when selecting the correct rail system for the trail bridge are:

- Who are the trail users—hikers, bikers, ATV riders, or

some combination of these users?

- Where is the trail bridge located—urban, rural, or

remote location?

- Does the trail bridge require a rail system or just curbs? An analysis must be completed to determine the need for a rail system.

After answering these questions, use the trail bridge design criteria table (table 1) to determine the required railing height for the trail's uses. For example, if the trail is for bikes or horses, the required railing height is 54 inches.

Notes:

- For trail bridges that require access for light administrative vehicles, a minimum width of 8 feet is required. The design

live load shall be AASHTO H-5 (10,000 pounds) vehicle loading.

- Widths shown are recommended minimum clear widths between railings or curbs. Use design parameters developed for

each particular trail, which may recommend narrower bridge width. If groomers are to be used on the trail, check the

specific groomer machines for the necessary width.

- See section 7.62 for a description and minimum requirements of pedestrian live load.

- Railing height is the minimum if railing is required. Provide analysis to determine whether railings may be eliminated.

- Except that footlog bridges should not be less than 10 inches.

Choosing a trail bridge rail system can be confusing, but knowing the three different types makes the selection process easier. If you follow the simple process described in this tech tip, determining the rail system required for your trail bridge will be straightforward.

ReferencesAASHTO. 2007. AASHTO LRFD (Load and Resistance Factor Design) bridge design specifications, 4th ed. Washington, DC: American Association of State Highway and Transportation Officials.

Faller, Ronald K.; Rosson, Barry T.; Sickling, Dean L.; Ritter, Michael A.; Bunnell, Steve. 1995. Design and evaluation of two bridge railings for low-volume roads. In: Vol. 2, Proceedings of 6th international conference on low-volume roads; 1995 June 25-29; Minneapolis, MN. Washington, DC: National Academy Press: 357-372.

International Code Council, Inc. 2006. International building code. Country Club Hills, IL: International Code Council, Inc.

Neese, J. 2002. Trail bridge railing geometry: summary of work and preliminary recommendations. Unpublished report available from Scott Groenier at Missoula, MT: U.S. Department of Agriculture Forest Service, Missoula Technology and Development Center.

Occupational Safety and Health Administration. 29 CFR Part 1910, Subpart D. Washington, DC: Occupational Safety and Health Administration.

U.S. Department of Agriculture Forest Service. 2005. Forest Service Handbook 7709.56b Transportation structure handbook. Washington, DC: U.S. Department of Agriculture Forest Service.

About the AuthorJames "Scott" Groenier, professional engineer, began working for MTDC as a project leader in 2003. Scott earned a bachelor's degree in civil and environmental engineering from the University of Wisconsin at Madison and a master's degree in civil engineering from Montana State University. He worked for the Wisconsin and Illinois State Departments of Transportation and with an engineering consulting firm before joining the Forest Service in 1992. He worked as the east zone structural engineer for the Eastern Region and as a civil engineer for the Ashley and Tongass National Forests before coming to MTDC.

For additional information about trail bridge rail systems, contact MTDC:

USDA Forest Service

Missoula Technology and Development Center

5785 Hwy. 10 West

Missoula, MT 59808-9361

Phone: 406–329–3978

Fax: 406–329–3719

Electronic copies of MTDC’s publications are available on the Internet at:

Forest Service and Bureau of Land Management employees can search MTDC’s documents, CDs, DVDs, and videos on their internal computer networks at: