Specific Design Applications

Most of the applications shown can be integrated into standard trail turnpike construction specifications. To simplify the illustrations, not all the components of a complete turnpike (ditches, curb rocks, or logs, etc.) are shown. Curb logs or rocks may be needed to confine tread fill unless the fill materials are quite granular. Shoulders must be maintained to keep geosynthetics covered to protect them from ultraviolet light and traffic abrasion. The figures are simplified cutaway cross-sectional views of the trail. They normally look much better on paper than they do during construction.

Geosynthetics usually are placed directly on the ground without excavation. Many of the illustrations show the various applications with a sag in the native soil surface along the center of the trail alignment. This sag is caused by adding the weight of the tread fill. The actual amount of settlement is very site specific and depends on soil type, level of saturation, and weight of tread fill used. Less tread fill can be used over geosynthetic products that are rigid or have high bending strengths because the weight of fill is distributed over a larger area. Settlement decreases when less fill is needed to obtain a stable tread surface. For example, much more tread fill is required for a single layer of geotextile (figure 10), than for geocell with geotextile (figure 11). In this example, the cost of importing tread fill must be compared to the increased cost of the geocell.

Figure 10—Typical placement of geotextile or geonet through flat,

boggy areas.

Figure 11—Geocell with geotextile and permeable tread material.

All alternatives that use tread fill should have a crowned or outsloped surface to help shed water quickly, improve stability, and control erosion and sediment production. Additional tread fill may be needed to rebuild the crown after the trail settles initially. More imported fill will be needed to maintain the crown if tread wear is high. Alternatives are compared in table 2.

Single-layer geotextile or geonet (see figure 10) separates fill material from saturated soils and distributes fill weight so less settling takes place. Because geonets cost more, use them only where drainage and subsurface moisture conditions are worst. Avoid using organic, silt, or clay soils for trail tread material because little subsurface drainage will occur and the trail tread will become muddy in wet weather. Rocky soils or crushed aggregate should be used as a tread material if possible. These materials retain much of their strength when saturated. Excess surface moisture can drain off through these permeable materials if the trail is located on a grade or side slope.

Geotextile With Encapsulated Free–Draining Rock

In the sausage technique (figure 12), the geotextile provides separation from the saturated soil, and the rock provides drainage for excess water. Twenty-five-millimeter (1-inch) flexible plastic pipe outlets for subsurface water may be desirable where trails are constructed on very flat terrain to avoid the "bath tub" effect. If the trail has grade or is built on a sideslope, other drainage options exist. The rock may be single-size material from pea gravel size to cobbles (75 to 300 millimeters or 3 to 12 inches), or it may be a mixture of rock materials that does not contain silt or clay. The rock can be just one layer thick if drainage is all that is needed. For reinforcement, at least 75 millimeters (3 inches) of rock would be recommended. The geotextile is wrapped over the rock layer with a 300-millimeter (12-inch) overlap to ensure encapsulation, because settlement of saturated soil can pull the overlap apart.

![Drawing of the encapsulation technique. In the drawing the text reads, Free-draining rock, Direction of travel, Tread fill material, and Geotextile (300 millimeters [12 inches] overlap at center).](images/fig12.jpg)

Figure 12—The encapsulation or "sausage" technique, with

native rock used for drainage.

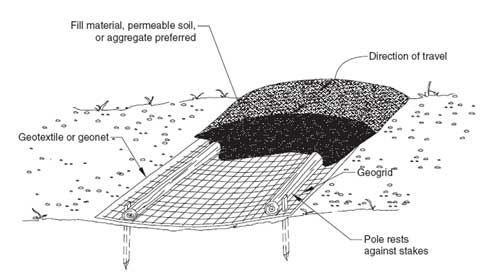

Geogrid With Geotextile or Geonet

Figure 13 shows geogrid placed on top of the geotextile or geonet to add bending strength to the system, decrease settling, and reduce the amount of fill material required. Very little drainage is required with this design, unless geonets are used or the tread material is permeable (rocky soils or crushed aggregate). The geogrid should be pulled taut to remove wrinkles before staking. The stakes and poles provide some pretension of the geogrid, better using its strength. The geotextile or geonet provides separation from the saturated soil and keeps the drainage paths along the bottom of the fill material from clogging. See Section 964 of the "Standard Specifications for Construction and Maintenance of Trails" (1996) for additional information.

Figure 13—Geogrid with geotextile or geonet.

Sheet drains under tread fill (figure 14) provide separation from saturated soils and distribute the weight of the trail tread to limit settling. Install the product with the plastic core side facing up and the fabric side facing down. This orientation takes advantage of the plastic core's compressive strength and the fabric's tensile strength, reducing the amount of settling and the amount of tread fill required. Twenty-five-millimeter- (1-inch-) diameter flexible plastic pipe can be used as a drainage outlet to take full advantage of the sheet drain’s capabilities. If the trail is on a grade or side slope, an outlet pipe or daylight section could provide drainage.

Figure 14—A sheet drain under fill material.

Sheet Drains or Geonets Used as Drainage Cutoff Walls

If a section of trail is on a side slope where subsurface water saturates the uphill side, a cutoff wall can be constructed to intercept surface and subsurface moisture (figure 15), helping drain and stabilize the trail section. This application is especially beneficial where the cut slope sloughs continually, filling ditches. The sheet drain or geonet should be installed within 1 meter (3 feet) of the trail's edge. The proper depth of the collection pipe and location of the sheet drain can be determined by probing the saturated soil with a short length of Number 4 reinforcing steel (rebar). Collector and outlet pipes can be made from flexible plastic pipe. Keep the top edge of the drain above the ground to capture surface runoff moving down the slope. Cover the exposed material with large rocks to protect the material from ultraviolet light. The collector pipe can be drained into an outlet pipe or with a sheet drain or geonet panel installed under the trail. This application requires ditching to intercept and drain water. Ditching is normally more extensive on flatter terrain.

Figure 15—A sheet drain or geonet used to intercept seepage.

Geocell With Geotextile and Permeable Tread Material

Geocell provides confinement chambers that distribute the trail tread loads over a wider area and reduce settling (see figure 11). Geocell works best in sandy soils, rocky soils, crushed aggregate, or free-draining rock, where it increases the tread's load-bearing capacity and prevents feet and hooves from punching holes into the trail. The geotextile provides separation between saturated soil and the tread fill material. Less tread fill will be needed with geotextile because settling is reduced. There is no subsurface drainage if the trail is on flat ground. If the trail has a grade or is built on a side slope, moisture will drain through the permeable tread fill. Organic, silt, and clay soils are not desirable as fill for geocells because these soils will probably remain saturated and unstable, meaning they will not be strong enough to carry the loads on the trail. Geocell does not increase the load-bearing strength of clay or silt.