Introduction

Soils can become deeply compacted in areas tracked by heavy equipment during timber harvesting, firefighting, fuel reduction, cultivation, or other forest management operations. Layers of compacted soil restrict the movement of water, air, and roots, reducing the survival and growth of trees and other plants.

Compacted layers typically develop 12 to 22 inches below the surface where conventional cultivators can't reach. These layers require special equipment called subsoilers, sometimes known as rippers (figure 1), to fracture them. This report offers some background on subsoilers and general guidelines on their use to break up compacted layers and return the soil's structure to a more natural state.

- Heavy equipment used in logging, firefighting, and other forest management operations can compact soils.

- Often, the compacted layers are 12 to 22 inches below the surface.

- Subsoilers can break up the compacted layer without destroying surface vegetation or mixing soil layers.

- This report contains information on subsoiling equipment and its use for land and forest managers who need to break up compacted soils.

Figure 1—This three-shank subsoiler attaches to a tractor's three-point hitch.

It can fracture compacted layers 12 to 22 inches below the soil surface.

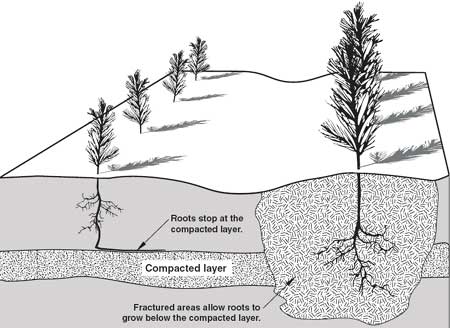

Subsoiling fractures compacted soil without adversely disturbing plant life, topsoil, and surface residue (figure 2). Fracturing compacted soil promotes root penetration by reducing soil density and strength, improving moisture infiltration and retention, and increasing air spaces in the soil.

How effectively compacted layers are fractured depends on the soil's moisture, structure, texture, type, composition, porosity, density, and, clay content. Success depends on the type of equipment selected, its configuration, and the speed with which it is pulled through the ground. No one piece of equipment or configuration works best for all situations and soil conditions, making it difficult to define exact specifications for subsoiling equipment and operation. Adjustments will be required for most projects. A partial list of equipment vendors is included at the end of this report.

Research data and vendor information generally agree that three main factors contribute to effective subsoiling:

- Subsoiling works better during drier soil conditions.

- Winged tips on shanks improve soil fracturing.

- Heavy clay soils are very difficult to break up.

Figure 2—This illustration shows how fracture zones created by a subsoiler can

help

promote deep, healthy root systems. Ideally, the soil is fractured with

minimal

disruption to the soil surface and existing plant life.