Discussion

The portable conveyor system is clearly capable of moving wood chips from thinned areas. The problems noted with conveyor overflow could be addressed by modifying the loading hopper design and/or the discharge spout of the chipper. Continuous side extensions would be needed to prevent chips from falling off the sides of the conveyor and to direct material flow past the overlap between sections. The productivity of the chipping system would probably be limited by the conveyor's capacity (figure 6).

During these tests manual loading rates ranged from 3 to 6 green tons per productive hour. Slash farther from the conveyor line took more time to handle. Placing slash on the conveyor was not difficult and the belt took material away quickly. When two people arrived at the belt at the same time, one of them would have to wait slightly for the belt to clear.

Slash presented numerous problems on the conveyor. Pieces hanging over the edges of the side extensions often hung up between conveyor sections or got caught in gaps in the extensions themselves. Large round pieces of slash rode on top of the cleats and sometimes rolled backward down the belt. The system as tested could not transport raw slash. Extra workers were needed to keep the material flowing to the roadside, simulating productivity as if the system were configured to keep pieces of slash on the belt. Because slash is not as dense as wood chips, the slash loading rate is less consistent than the chipper's loading rate. The potential productivity of the portable conveyor system carrying slash is less than half that for carrying chips.

One of the requirements for a system that can be used in the woods is the ability to span rough terrain. A variety of methods were used to block up conveyor sections, including adjustable leg sets, cribbing blocks, and slash pieces. The system was configured to cross rocks, logs, and variations in terrain. A solid installation is important to avoid downtime when the conveyor separates or collapses. The tradeoff is extra time needed for setup.

Figure 6—Theoretical production of a conveyor

carrying wood

chips at a density of 10.5 pounds per cubic feet

(fpm stands for feet per minute).

The cost of the system is mostly the capital cost of the basic conveyor plus accessories. New models with more powerful motors only allow four sections to be connected electrically on one 30-ampere circuit. Four 10-foot sections complete with power, cables, side extensions and other gear would cost about $17,400. Assuming 2,000 scheduled work hours per year, a 5-year life, 75-percent productive time, 0.5 gallons per hour fuel consumption, 15 percent salvage value, and 20 percent for profit and overhead, this system would cost about $4 per productive hour for a 36-foot run. Costs are essentially a function of the length of the conveyor system (figure 7). Thus, a 180-foot conveyor line would cost $20 per productive hour. The system as demonstrated in the field would have cost about $11.70 per productive hour for purchase and operation, including overhead costs.

The manufacturer of the portable conveyor system we used recommended that a different configuration would be better for moving slash. Specifically, a wider belt (20 inch), three-phase motors, faster belt speed (85 feet per minute) and wider side extensions might address many of the problems observed during the field test. According to product specifications, a single generator could power up to thirteen 10-foot conveyor sections using three-phase motors. With the wider belt, each conveyor section weighs about 210 pounds and costs about $3,590. The extra cost of the threephase motors is offset to some degree because the motors can power more than one section. Most of the accessories would be the same as with the tested configuration.

Figure 7—Cost per productive hour for the portable

conveyor system as a function of the conveyor's

distance into the stand.

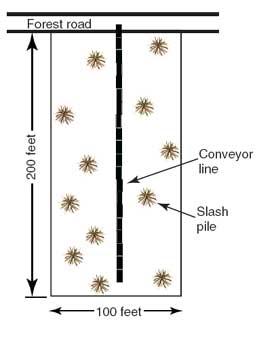

Assuming that the wider conveyor could handle the slash effectively, the limiting factor in the system's productivity would be the production rate of the crew. Studies of post-and-pole crews and shortwood crews found that five workers can fell, lop, and pile about 3 green tons per hour. The demonstration tests showed that if the slash can be kept on the belt, the conveyor could move it. If the crew's ability to keep up is the limiting factor, the ideal setup would require slash to be dragged no more than 50 feet or less. Assuming slash was being removed for 50 feet on either side of the conveyor, a 200-foot conveyor section would allow slash to be removed from about 0.5 acre (figure 8). This system (not including labor to operate it) would require about $115,000 in equipment and would cost about $27 per productive hour.

Figure 8—One potential layout for a

portable conveyor system.

A spreadsheet was developed to compare alternative conveyor system layouts and operating costs. Total treatment costs increase as the fuel loading per acre decreases. The cost per ton of slash removed increases with the length of the conveyor because of the additional capital cost of each section. The labor required to pile or pull slash to the belt accounts for over half of total cost (figure 9). Setup cost for the conveyor (per ton removed) is significantly higher than the cost of moving the slash.

Figure 9—Distribution of costs for

removing slash with a 200-foot

conveyor when the slash is chipped

in the woods.

Setup time is significant, particularly when the volume per acre is low. The total area accessed by a conveyor line is less than 1 acre, meaning that the costs of setup and takedown are charged to a relatively small amount of material. Setup and takedown tasks include clearing an area for the conveyor line, carrying the conveyor sections into the woods, blocking the conveyor sections, connecting the power, setting up the generator, attaching all side extensions, and attaching other accessories. Costs are affected by many variables, including strip width, extraction distance, volume per acre, piling productivity rates, and setup times. Specific conveyor applications should be carefully analyzed to understand the nature of these interactions.