|

|

Technology & Development Center |

| June 2008 | 7300 | 0873-2333-MTDC |

Ted Etter, Project Leader

The Forest Service, U.S. Department of Agriculture, has many lookouts and communication facilities that are subject to lightning strikes. In some regions, only licensed electricians with credentials in lightning protection are allowed to install and repair lightning protection systems. However, Forest Service personnel who understand the fundamental requirements of lightning protection can perform initial inspections and identify problems.

Careful visual inspection is the primary way of identifying shortcomings in the wiring and bonding that carry current from a lightning strike to the ground. Some specialized tools can help inspectors identify poor or missing connections to the grounding circuit.

The standards for wiring and grounding structures to provide protection from lightning strikes are well established. The "Additional Information About Lightning Protection" section at the end of this tech tip lists several standards that specify materials and methods used in lightning protection. Two suppliers of approved hardware also are listed.

The Forest Service's standards for lightning protection are based on Class II standards for structures 75 feet tall or taller. These standards call for down and main conductors to be stranded copper conductors ½ inch in diameter or larger. Bonding wire should be stranded copper conductors at least ¼ inch in diameter. Lightning protection on older lookouts was not built to these standards, but may still be okay if the conductors are in good shape and junctions have not corroded.

A lightning protection system protects the occupants and contents of a structure from the potential harm of a lightning strike. Lightning is a brief surge of electrical current that reduces the voltage difference between the earth and an electrical charge that has accumulated in the atmosphere. Air terminals, main conductors, and ground rods or radials are the primary components of a lightning protection system. They provide a favored path for the electrical current of a lightning strike around the structure, preventing the current from passing through occupants and equipment. Additional wiring serves to shield interior spaces. Surge arresters reduce the likelihood of damage to electrical hardware inside the structure.

Air terminals atop a structure must be connected to grounding rods or radials with large-gauge wire. Permanent metal objects around and within the structure must be electrically bonded to the ground wiring. In essence, a wire box outlines the structure, shielding persons and equipment inside, in the event of a lightning strike. Through age, negligence, or vandalism, a structure's protective wiring may not ensure protection for the occupants. Careful visual inspection is the primary way of identifying shortcomings in ground wiring and bonding. Such inspections should be performed annually, especially before a structure is first occupied for the season.

The following fundamental standards are typical for inspection of lightning protection at a Forest Service lookout:

Figure 1a—This improper substitute for an

air terminal

is made from copper wire.

Figure 1b—These proper air terminals are constructed

of ½-inch diameter copper rods and have at least two

conduction paths to an earth ground.

Figure 2—Down conductors should be secured to the

structure and not permitted to move or flex.

Older installations that use ¼-inch solid copper wire for down conductors and No. 6 stranded copper wire (0.16-inch diameter) or larger for bonding are acceptable, providing splices and junctions are not corroded and do not have more resistance than allowed according to the specifications in this tech tip (see the section on "Performing Inspections"). Figure 3 shows an improper junction.

Figure 3—This wire junction doesn't

use connectors approved for

lightning

protection on down conductors.

Note

the arc damage from lightning strikes.

Copper is the conductor of choice for connecting the components of a lightning protection system. While silver is a better conductor than copper, it costs more. Large-gauge copper wire is used for the main conductors that connect air terminals (lightning rods usually made of solid copper) to the grounding network. Smaller gauge wire may be used to connect metal objects such as window frames and metal construction hardware to the main conductors. Wiring connections must use hardware that minimizes electrical resistance at the junction and that prevents corrosion to maintain the junction's low resistance.

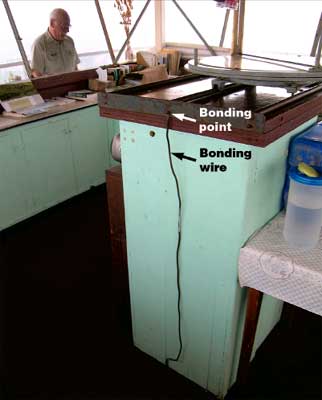

One of the functions of the complete lightning protection system is to minimize the voltage difference between metal objects in and around the structure during a lightning strike. For instance, large voltage differences between a down conductor and a wood stove inside a cabin can lead to arcs (side flashes) that may harm occupants and equipment inside the cabin. Metal objects such as stoves, window frames, fire extinguisher holders, and plumbing fixtures must be bonded with copper wire to the main conductors (figure 4). In addition, framing the cabin in a wire outline shields the contents of the cabin from high voltage potentials outside during a lightning strike.

Figure 4—This bonding wire is attached to a

fire finder inside a Forest Service lookout.

Bonding also extends to metal components outside the cabin. Wire mesh around handrails, metal piping from propane tanks, metal plates in the structure's support, and antenna cabling must all be bonded to the main conductors. Bonding requires approved methods and hardware to ensure good electrical and mechanical connections to the main conductors. Figures 5 through 7 show improper bonds for structural metal. Figure 8 shows proper bonding.

Bonding conductors are made of stranded copper wire, typically ¼ inch in diameter (No. 14 bonding wire) under the Class II standards. Old bonding conductors 1⁄8 inch in diameter (No. 10 bonding wire) are still acceptable if they're in good condition.

Figure 5—Radio coaxial cable should be bonded at

the base of an antenna mast; this cable isn't.

Figure 6—The bonding wire should be connected

to the solar panel mounting bracket.

Figure 7—The gusset plate is not bonded to

the down conductor.

Figure 8—The steel brace on the left is bonded to the

down conductor on the right.

The quality of the electrical ground installed at the site will determine the success of lightning protection. At locations with frequent rainfall and deep organic soil, a good connection to earth ground is relatively simple. Four 10-foot copper ground rods will probably meet the conductivity specification of less than 20 ohms of resistance to earth ground.

For structures on rocky surfaces or shallow, dry soil, getting a good earth ground is not as easy. Under such conditions, radial wires can be run out from the structure and ground enhancement material (GEM) can be used to improve the earth ground.

Inspecting lightning protection systems requires determining whether the specified conductors and connections exist and whether connections appear to be mechanically sound and free from corrosion. Many lookout inspections have found that the main conductors were physically damaged or had been removed entirely. A common fault is the failure to bond metal items in and around the cabin to the main conductors.

Another part of lightning protection is the wire cage around the cabin (figure 9). There should be wire rings around the cabin at both the roof and floor levels. Both rings should be tied to the down conductors. Older installations included radial wires under the floor of an elevated cabin to complete the wire cage, but radial wires are not required by current standards.

Figure 9—A wire cage provides lightning protection under

the floor of a lookout cabin.

Specifications for lightning protection systems require very low resistance. The wire clamps that join main conductors should have a wire-to-wire resistance of no more than 1 milliohm. The ½-inch stranded copper wire that is the minimum size for down and main conductors in the Class II standard has a resistance of less than 0.1 ohm per 1,000 feet. The resistance of short runs should be in the milliohm range. Runs from the top of a cabin to ground level include at least four down conductors, so the net resistance end-to-end is still on the order of milliohms. Table 1 summarizes key specifications for lightning protection systems.

The low resistances and multiple paths for current in the protection network challenge the capabilities of conventional ohmmeters or multimeters to evaluate the quality of the wiring. Typical digital multimeters have a resolution of one tenth of an ohm. Evaluating wire junctions or bonding connections using such meters should give indications of one or no counts (tenths of an ohm) above the value indicated when the meter's test leads are shorted together.

Conventional ohmmeters can be used to test bonded items that have only one connection to a main conductor for a single-circuit junction between an air terminal and a down conductor. Conventional ohmmeters are less effective for testing the resistance of a junction including main conductors because most junctions occur in parallel circuits.

Some measurement tools can be used to test the quality of the earth ground and the resistance of wire junctions. Additional tools are being evaluated and developed at the Missoula Technology and Development Center (MTDC) for measuring ground resistance on sandy or rocky soils and for measuring wiring resistance over long runs. Evaluations of those tools and recommendations for their proper use will be covered in a future document.

Many of the specifications for lightning protection systems are driven by "NFPA 780, Standard for the Installation of Lightning Protection Systems: 2008 Edition" from the National Fire Protection Association. Standards for Forest Service lookout protection generally require the Class II materials specified for structures taller than 75 feet.

The Forest Service's Intermountain Region (R4) has prepared two specifications for lightning protection:

These specifications are available on the Forest Service's internal computer network at: ftp://ftp.r4.fs.fed.us/pub/engineering/csi_specs/Region%204%20MasterSpecs/R4_Specifications _Varying_See_Readme/26_Electrical/

Harger Lightning & Grounding (http://www.harger.com) supplies air terminals, wiring, ground rods, and junctions.

Erico International Corp. (http://www.erico.com) supplies ground enhancement material and CADWELD copper joint welding.

Thanks to Shane Brown, Region 4 electrical engineer, for specifications on protection systems and to Steve Oravetz, Region 1 facility group leader, for lookout tours.

Ted Etter joined MTDC in 2002 as an electronics engineer and project leader. He has 20 years of experience working for private industry in the design of test equipment, display devices, and medical instrumentation. For 6 years before he joined MTDC, Ted taught courses in the electronics technology program at the University of Montana College of Technology, Missoula. His work at MTDC includes projects in wireless communications, alternative energy sources, instrumentation, and process control. Ted received a bachelor's degree in mathematics from the University of Oregon and a master's degree in teacher education from Eastern Oregon State University.

Electronic copies of MTDC's documents are available on the Internet at:

http://www.fs.fed.us/eng/t-d.php

For additional information about lightning protection, contact Ted Etter at MTDC:

USDA Forest

Service

Missoula Technology and Development Center

5785 Hwy. 10 West

Missoula, MT 59808–9361

Phone: 406–329–3980

Fax: 406–329–3719

E-mail: tetter@fs.fed.us

Forest Service and Bureau of Land Management employees can search a more complete collection of MTDC's documents, CDs, DVDs, and videos on their internal computer networks at:

http://fsweb.mtdc.wo.fs.fed.us/search/

The Forest Service, United States Department of Agriculture (USDA), has developed this information for the guidance of its employees, its contractors, and its cooperating Federal and State agencies, and is not responsible for the interpretation or use of this information by anyone except its own employees. The use of trade, firm, or corporation names in this document is for the information and convenience of the reader, and does not constitute an endorsement by the Department of any product or service to the exclusion of others that may be suitable. The U.S. Department of Agriculture (USDA) prohibits discrimination in all its programs and activities on the basis of race, color, national origin, age, disability, and where applicable, sex, marital status, familial status, parental status, religion, sexual orientation, genetic information, political beliefs, reprisal, or because all or part of an individual’s income is derived from any public assistance program. (Not all prohibited bases apply to all programs.) Persons with disabilities who require alternative means for communication of program information (Braille, large print, audiotape, etc.) should contact USDA’s TARGET Center at (202) 720-2600 (voice and TDD). To file a complaint of discrimination, write to USDA, Director, Office of Civil Rights, 1400 Independence Avenue, S.W., Washington, D.C. 20250-9410, or call (800) 795-3272 (voice) or (202) 720-6382 (TDD). USDA is an equal opportunity provider and employer.

|

| Top |

| USDA Forest Service, Technology and Development Last Modified: 03/30/2013 03:06:33 |