Back | Next | Home

Missoula Technology &

Development Center

| Table

of Contents Back | Next | Home |

Missoula Technology & Development Center |

Treatment of Petroleum-Contaminated Soils

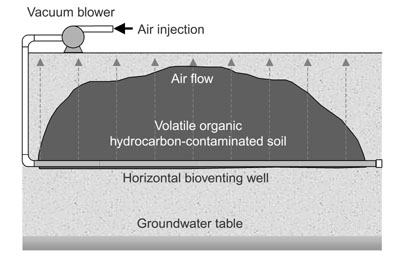

In bioventing, as in SVE, vacuum in a well or wells screened (open to air flow) through the unsaturated soil pulls air though the soil. Even though some volatile compounds are removed by volatilization, bioventing relies primarily on biological degradation to remove contaminants. Petroleum hydrocarbon compounds that are amenable to biodegradation were discussed previously. Figure 16 shows a schematic of a typical bioventing system.

Figure 16—Schematic of a typical bioventing system.

One difference between bioventing and SVE is the desired airflow rate. Because bioventing attempts to reduce the mass of contaminant by biodegradation, lower airflow rates are used, reducing the volatilization of the contaminants. Reducing the volatilization rate reduces the mass of volatile contaminant that will require treatment in the gaseous phase. Figure 16 illustrates a bioventing system designed so that the extracted soil gas does not have to be treated. Barometric pumping can also be used to supply oxygen to the subsurface, assisting aerobic biodegradation.

The main limitation to the use of bioventing in cold regions is probably the reduction in biodegradation because of low temperatures. In Alaska, field tests have shown that heating and insulating the soil during bioventing can maintain adequate rates of biodegradation. Bioventing with three different methods of soil heating was tested on soil contaminated with JP–4 jet fuel near Fairbanks, AK. The soil was heated by circulating extracted heated ground water through the unsaturated contaminated soil, by passive solar heating, and by heating the soil with heat tape. The soil was insulated for all three techniques to help retain the applied heat. Results from these three field tests were compared to a neighboring site where bioventing was attempted with no applied heat. Heating of the soil substantially increased biological activity and contaminant reduction.

Challenges faced for bioventing in wet, remote regions are similar to the challenges faced for SVE. Using barometric pumping to introduce air into the subsurface may make bioventing attractive in remote regions.

Table 17 shows the items to be considered when developing a cost estimate for bioventing. The assumptions include:

| Cost estimating factors | |

|---|---|

| • | Mobilization and demobilization. |

| • | Piping. |

| • | Slotted pipe or well screen. |

| • | Gravel pack for area around screens. |

| • | Blower. |

| • | Liner (if required). |

| • | Housing for the blower and generator. |

| • | Fuel for the generator—Estimated fuel consumption is one-half gallon per hour. |

| • | Confirmation sampling—The number of samples depends on the size of the contaminated site and on the regulatory agency. |

| • | Accommodations at the site during system insallation. |

| • | Operation and maintenance visits. |

|

|

Back | Next Table of Contents |

Missoula Technology & Development Center |