A Guide for Conducting Facilities Condition Assessment Surveys

Accessibility

Older facilities may not be accessible for persons with disabilities. An accessibility survey and transition plan are required for all USDA Forest Service buildings that are not accessible. The survey and transition plan will contain details of work required to make the buildings accessible. However, for budgeting and planning purposes, note basic building accessibility issues in the condition survey. Office entries and bathrooms are the most critical features for accessibility. More information is available at http://fsweb.mtdc.wo.fs.fed.us/toolbox/acc.

Mold in buildings has gained attention lately because of its serious potential health risks. Any moisture or mold problems should be noted during the condition survey. Mold can damage building materials, finishes, and home furnishings. Some molds can cause structural damage to wood and other building components. In addition, mold may cause health problems for some individuals. More information about mold is available at the Facilities Toolbox Forest Service Web site at http://fsweb.mtdc.wo.fs.fed.us/toolbox/haz/haz04.htm.

All Forest Service buildings should have been inspected for asbestos by an accredited asbestos inspector during the 1990s. If any materials containing asbestos were discovered, the building should be posted with warning signs and have an asbestos management plan. However, some buildings were missed and some asbestos-containing materials were overlooked during inspections. Composition flooring, popcorn ceiling texture, cloth- or plaster-covered pipe, duct insulation, or loose-fill vermiculite insulation installed before 1981 may contain asbestos. Check the asbestos inspection report if the material is deteriorating or before recommending any work that could disturb the material. If the material is not listed in the asbestos inspection report, have it inspected. See the Facilities Toolbox Forest Service Web site (http://fsweb.mtdc.wo.fs.fed.us/toolbox/haz/haz02.htm) for more information about asbestos.

Lead-based paint was used on all types of buildings before 1978. Lead-based paint that is in good condition usually is not a hazard. However, lead dust can form when the paint is scraped, sanded, or heated. Lead exposure may cause a range of health effects, which can be particularly acute in children 6 years old or younger. Abatement of lead-based paint may be needed when painted surfaces are being renovated or when paint is deteriorating, particularly in family housing units. More information on lead-based paint is available at the Facilities Toolbox Forest Service Web site (http://fsweb.mtdc.wo.fs.fed.us/toolbox/haz/haz03.htm).

In 2004, CCA (chromated copper arsenate)-treated wood products were restricted to certain industrial and commercial uses, bringing preservative treated wood to the public's attention. The arsenic and other toxic chemicals in wood that has been pressure treated to resist rot and insect damage are of particular concern in areas where children may come into contact with the wood. It may be prudent to assure that older pressure-treated lumber at USDA Forest Service family housing units or at daycare facilities in USDA Forest Service buildings is either completely covered with a good coat of paint or is replaced with material treated with less toxic chemicals. More information on pressure treated wood is available at the Facilities Toolbox Forest Service Web site (http://fsweb.mtdc.wo.fs.fed.us/toolbox/haz/haz15.htm).

Fire lookouts (figure 7) are unique structures in the USDA Forest Service's inventory of buildings. Many of them are quite old and in various states of disrepair. Lookouts may be staffed during the fire season, rented to the public, or unoccupied. Most are remote, exposed to severe weather, and do not have electricity or other commercial utilities.

Lightning protection is required on lookouts and should be checked during condition surveys. Structural support systems, including guy wires, should be tight and in good repair. Propane is often used at lookouts. Fuel tanks should be secured and located as required by code. The requirements differ based on tank size. The tanks also need to be located where they will not damage the lookout if they are vandalized. Information on lightning protection, propane systems, wood stoves, and guy cables for lookouts is available at http://fsweb.r1.fs.fed.us/e/facilities/facilities_index.shtml.

When lookouts are rented to the public, they must meet code requirements for public use. The requirements most likely to require attention are stairway tread and riser dimensions, guardrail height, and intermediate rail spacing. Because of liability concerns, the public should be prevented from unauthorized access to lookout towers. Fences, gates, and locks are appropriate.

Figure 7—The Horn Lookout Tower in the

St.

Francis

National

Forest is a standard steel

lookout

tower built in the early 20th

century.

The location and nature of some USDA Forest Service facilities make them attractive places for critters. Mice and other rodents can damage buildings and create health hazards for humans. Especially if mouse droppings or nests are visible, precautions must be taken to avoid exposure to hantavirus during the inspection. Any rodent activity or presence should be noted during the condition survey. A tech tip, Controlling Rodents in Forest Service Facilities: Reports from the Field (0471–2332– MTDC) is available at http://fsweb.mtdc.wo.fs.fed.us/pubs/htmlpubs/htm04712332.

There is no substitute for on-the-job training with experienced inspectors. Learning by doing and getting the opportunity to see first hand how to conduct a condition survey can significantly shorten the time it takes to become proficient. New facilities engineers are urged to consider accompanying an experienced engineer on several condition surveys before attempting a solo inspection, or to have the experienced inspector accompany the new inspector on the first few inspections. Experienced facilities engineers at other USDA Forest Service units usually are willing to assist less experienced engineers. Above all, a facilities engineer must know when to involve specialists or those with more experience. It's okay to say, "I don't know, but I'll find out."

Since October 2001, the USDA Forest Service has recognized the international family of building codes for the design of buildings and related facilities. Forest Service Handbook 7309.11 Zero Code, part 06 (http://fsweb.wo.fs.fed.us/directives/fsh/7309.11/7309.11_zero_code.doc) details the technical standards and codes that must be followed for new construction, leased buildings, and existing Forest Service buildings. They include accessibility guidelines, safety codes, the Built Environment Image Guide, and energy standards. This section of the handbook also explains what to do if codes and standards conflict. Facilities engineers conducting condition surveys need at least a cursory knowledge of these codes and how to use them.

Code training by International Code Council (ICC) chapters and private companies is readily available. USDA Forest Service engineers and architects have found the code training put on by the Colorado Chapter of the ICC, the University of Texas Construction Research Center, and the Southern Nevada Chapter of the ICC (see Code Training in appendix A) to be high quality.

The Taunton Press (http://www.taunton.com) has published a set of handy code reference guides for field use, called Code Check (http://www.codecheck.com). These guides summarize the information found in the international codes in an easy-to-use, laminated, spiral-bound format suitable for field use. The guides even provide code references for each item to be checked. Appendix A provides information on these guides.

Facilities inspectors generally need a number of tools for a thorough condition survey. The "Tools of the Trade" chapter of the book Inspecting a House has a complete summary of useful inspection tools. Some of these tools, such as ladders, are available at most USDA Forest Service administrative sites. However, when inspecting remote facilities, inspectors must bring all the tools they will need. Screwdrivers, ladder, flashlight, pliers, tape measure, and an extendable mirror to look into hard-to-access areas should be part of the inspector's toolkit (figures 8 and 9). Specialty tools like moisture meters and electrical testing tools may be helpful when their capabilities and limits are understood.

Figure 8—A compact facilities inspector's toolkit.

Figure 9—A more extensive facilities inspector's toolkit.

An inspection form is a key tool for conducting a successful condition survey. Although few people enjoy completing forms, a detailed inspection form can serve as a reminder of all the building components that should be inspected. Forms also help standardize the data gathered and facilitate cost estimates. Many forms are available, but those generated within the USDA Forest Service seem to meet agency requirements the best. Chapter 40, section 44.7 of the Forest Service Handbook 7309.11 (https://fs.usda.gov/wps/myportal/fsintranet/!ut/p/c5/) requires use of the Maintenance Condition Survey Checklist (Form FS-7300-1) or a similar form that contains the elements of FS-7300- 1 for conducting and documenting inspections.

The Northern Region has developed an Excel spreadsheet for Building Maintenance Data Entry. Information about maintenance needs can be entered as the inspection is conducted using a laptop computer or can be handwritten and transferred to digital format later. The building description is based on information from the INFRA database. Estimates of the cost of repairs can be generated automatically within the spreadsheet. Cost adjustment factors can be applied to account for remote locations and the historic status of structures. Unit cost data in the spreadsheet is based on RSMeans cost data publications and must be updated annually and adjusted to customary local costs to remain accurate. The inspection items in the Excel spreadsheet, which is organized in Construction Specification Institute format, serve as a good checklist for a building condition survey. This spreadsheet automatically compiles cost data and sorts cost estimates to match the appropriate INFRA reporting categories: health and safety, mission, and resource protection.

Another frequently used inspection form is an expanded and reorganized Maintenance Condition Survey Checklist based on Form FS-7300-1. This form has space for more detail than the spreadsheet, but does not include cost data. It is a good form for an initial inspection of a structure and provides much of the data needed for the building's official records. These documents and others developed by experienced USDA Forest Service facilities engineers are available at http://fsweb.wo.fs.fed.us/eng/programs/facilities/surforms.htm. In the future, INFRA may have the capability to function as a field information-gathering tool, but until then, spreadsheets or other forms are being used by most facilities engineers.

Safety must be the first consideration during a condition assessment survey. Facilities engineers routinely inspect areas such as crawl spaces under buildings, attics inhabited by bats, and septic tanks. The potential for accidents is relatively high if inspectors aren't aware of the hazards and appropriate mitigation measures. Facilities engineers should complete a job hazard analysis (JHA) covering all aspects of their work and taking into consideration the specific tools they use and the situations they encounter. Example JHAs for most aspects of facilities inspection work and guidelines for creating other JHAs are available at http://fsweb.wo.fs.fed.us/OSOH/jha.html.

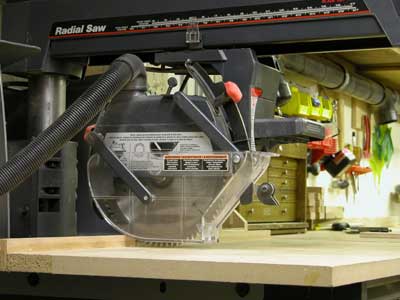

Facilities engineers also have a responsibility to help protect the people who use USDA Forest Service structures. Any situation discovered during a facilities condition survey that presents a risk to the safety or health of employees or the public should be brought to the attention of management immediately and scheduled for corrective work (figure 10).

Figure 10—Proper guards and shields on equipment and machinery are

important

safety devices that

may be noticed during facilities condition

assessment

surveys.

Although

this sort of safety hazard is

not technically

part of a condition

survey, missing guards and shields should be brought

to management

's

attention so the problem

can be corrected immediately.